The construction industry while being one of the most mechanized ones, still relies on manual labor and lacks automation across infrastructure building, repair, and maintenance. This has become even more prominent as the labor shortage has become more acute in recent years. According a study cited by ADP, approximately 41 percent of the current construction workforce in the US — including many people in management roles — will retire by the year 2031. This indicates that the industry will soon face a potential labor crisis.

In addition, according to Yahoo Finance, the industry requires an additional 500,000 workers beyond the normal pace of hiring to meet demand in 2024. Hence, there is a severe need to fill the demand-supply gap in the construction space. Automation using robots and drones has come to the fore as a viable solution. The use of robots in processes such as painting, repair, and inspection is expected to reduce the dependency on human labor by automating a major portion of related activities.

Robots and drones leverage vision and artificial intelligence to analyze building and bridge surfaces to determine the best action to be performed – whether it is deciding the thickness of the paint coat or nailing the walls.

In this article, we explore how robots and drones with the help of cameras and AI can help the construction industry overcome labor shortage, improve safety, and enhance productivity. We will discuss a wide variety of use cases in addition to learning the role of camera modules in making them possible.

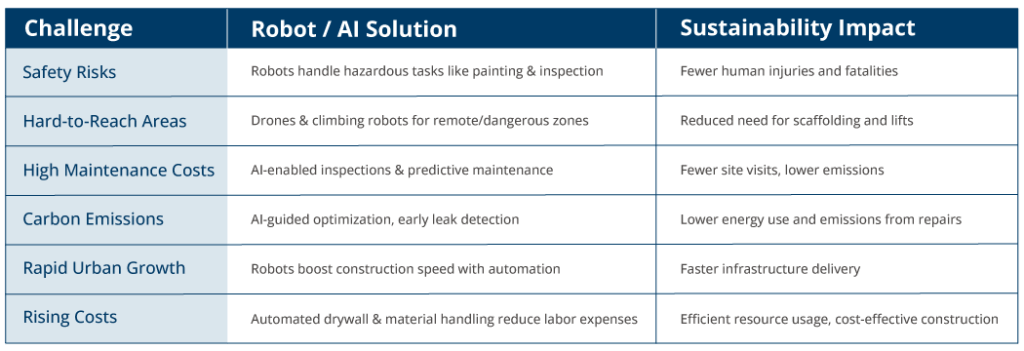

Understanding key challenges in the construction industry

There are many challenges facing the construction industry. For the purpose of this discussion, let us look at those where robots and drones can come in and make a difference.

Increasing accidents and safety hazards

According to the US Bureau of Labor Statistics, fatalities in construction increased by 11% from 2021 to 2022. It also states that a total of 1,056 construction workers died on the job in 2022. These incidents raise concerns about the safety and protection of construction workers. Even after having adequate safety measures, the nature of the job itself makes it difficult to monitor the well-being of workers on construction sites.

Difficulty in accessing certain areas

In construction, certain tasks – like drywall finishing for example – involve working on hard-to-reach areas. Another example is when a bridge or a large industrial area has to be inspected for repair or regular monitoring and maintenance. Such locations not only make access difficult but also pose a threat to the worker’s life and safety.

The need for regular maintenance

Monitoring of commercial and industrial infrastructure is labor-intensive, especially those involving large areas of land or buildings. Also, human inspectors can only be deployed once in a few days or weeks, making it almost impossible to conduct checks on a daily basis. Moreover, increasing labor costs prevent construction companies from employing more workers for inspection and maintenance.

Ever-increasing carbon emissions

According to the UNEP (United Nations Environment Program), the buildings and construction sector is by far the largest emitter of greenhouse gases, accounting for a staggering 37% of global emissions. The UNEP also states that this leaves the sector off track to decarbonize by 2050. This calls for serious interventions to protect nature for the generations to come.

Accelerated urban development

World Bank says that by 2045, the world’s urban population will increase by 1.5 times to 6 billion. This means that urban development has to happen at a much faster pace than before. The construction industry has a major role to play here since it forms the backbone of building urban infrastructure. From smart cities to connected cities, the speed of construction will become extremely important.

Increasing costs

The construction industry is characterized by huge capital investments. Heavy operations costs such as labor and maintenance expenses make things worse. In the US, the Building Cost Index increased 3.8% in 2023, while the Construction Cost Index rose 2.6% over the same period. Though the increase is not as steep as the previous couple of years, construction costs continue to rise. This in turn leads to an increase in real estate costs and related expenses.

How robots and drones can help address these challenges?

Next, let us look at how robots and drones are helping overcome some of these challenges by automating and easing various tasks in construction.

Painting buildings and ships

Industrial painting is a laborious task, especially when it comes to large buildings and ships. The traditional way of doing it manually takes a lot of time and requires a large workforce. Not to mention the safety challenges that come with it. Automating this process can lead to faster work completion while reducing human labor and saving costs in the long run. Industrial robots have come to the fore as a solution that helps to achieve this.

For example, PaintJet, a Tennessee-based startup is using robotics to automate large-scale industrial and commercial painting. It uses a combination of robots and drones to make this happen. Drones are used for inspecting the building or facility to study the surface. Based on the insights obtained, the necessary details like the thickness of the coat, amount of paint, time needed for completion, etc., are planned out. The next step involves the robot preparing the surface for painting by removing dirt, rust, or any unwanted contaminants. The final step involves applying the paint as per the requirements.

The application of robotics in industrial painting opens up new possibilities not just in the form of addressing labor shortage, but in reducing human fatalities and accidents. Danger-prone industrial facilities like nuclear power plants can hugely benefit from this, particularly during the repair or maintenance period.

Drywall finishing

Drywall painting and finishing is one of those trades in construction that has seen little automation. Though drywall finishing requires skilled labor, a major portion of it is repetitive, and most things repetitive can be automated. Today robots can be used for tasks such as the application and sanding of the finishing compound while humans can handle the taping and working on complex spaces and corners.

Robots used for drywall finishing today are smart and do not require project plans to be pre-loaded. They leverage a combination of 2D and 3D sensors to understand the nature of the space and ‘self-design’ the work routine accordingly. As these robots work on the field and collect more data, machine learning and AI algorithms can be leveraged to improve performance and automate more complex tasks.

Drywall finishing by a human

Industrial inspection

According to Invert Robotics, the American Society for Civil Engineers gave the US infrastructure a C-minus on its report card in 2023. This can be attributed to various reasons such as highly reactive gases in the environment, climate change, and natural calamities. These factors have a negative impact on the infrastructure leading to corrosion, expansion and contraction of steel and concrete, and other structural damages.

While regular inspection can solve this problem to some extent, using human workers to perform it has safety and operational challenges. Robots and drones can be a game-changer in a scenario like this.

Robots that can climb walls are used to inspect walls, rooftops, and steel holding tanks for corrosion and cracks. While wall-climbing robots need a surface to navigate on, drones can fly and inspect large areas in a short time. Some robots can also perform underwater inspections, making the process faster, especially in the oil and gas industry.

Promoting sustainability in construction with robotics

According to a report by Gecko Robotics and Rho Impact, digitizing carbon-intensive infrastructure could reduce emissions by 853 million metric tons (MMT) of CO2 annually. Robots have a great role to play in this journey by digitizing construction-related tasks such as the following:

- Preventing corrosion and gas leakages in factories, mines, and powerplants: Robots can combine the power of vision technology and AI to detect early signs of damage such as corrosion and gas leakage. By constantly monitoring industrial environments, robots can even predict the likelihood of a gas discharge or damage occurring. This otherwise would take many man-hours of work, which in turn will increase labor costs. It also contributes to a sustainable future by reducing carbon emissions.

- Inspection of large vessels: Leakages in ships and vessels lead to huge losses. They not only pose a threat to human life but negatively impact oceanic life. Robots can be used here to monitor the vessel and ensure that no leakages happen. AI can also be used here to optimize loads with the aim to prevent accidents due to overload.

- Inspection of bridges: By deploying robots to inspect bridges and collect data on them, repair and maintenance tasks can be completed faster. Moreover, the data collected using robots can further be analyzed using ML and AI to reduce carbon emissions by 10 MMT of CO2.

The role of cameras and AI in the robotic revolution

Beyond doubt, robotic and drone systems are making construction faster, and more importantly, safer. This would not have been possible without the use of cameras and AI. While cameras offer sight, AI acts as the intelligence behind certain actions of construction robots.

Cameras primarily help with the following two tasks:

- Autonomous navigation: Some robots can navigate autonomously by leveraging depth cameras. They use technologies like stereo or time of flight to measure the distance to nearby objects. This enables robots to navigate in their environment without running into obstacles. Some robots also use guided navigation with the help of lines or barcodes laid down on the floor.

- Capture images for analysis: Robots and drones use cameras to capture images of walls and other surfaces. For example, in the case of painting a ship, cameras in a drone can capture images of walls and other surfaces, which can then be fed into the system to determine parameters like type of paint and thickness of the coat. Similarly, in the case of an inspection robot, camera modules capture images for identifying cracks, fissures, and rust.

An inspection drone

- Guided navigation: In cases where a human is operating the robot or drone, cameras provide a real time feed to the operator for maneuvering it. Whether it’s for climbing a wall or flying around an area, cameras enable remote operation during inspection, painting, or repair tasks.

Essentially, cameras act as the ‘eyes’ of robots. The function of AI models is to analyze the captured image data and make decisions based on it. For example, by analyzing steel and concrete surfaces, AI models can predict when a crack could appear. Given below are some of the other benefits of integrating AI with vision technology in construction robots and drones:

- AI models can predict gas leakages by analyzing pipes and containers. This can save lives and prevent huge losses.

- By collecting image data over a period, ML models can be better trained so that AI engines can improve their accuracy.

- With the help of AI predictions and analyses, safety officers can implement measures to ensure safety in the respective areas.

The future of vision and AI-enabled robotics in construction

The robots of the past could only automate mundane tasks. We have come a long way from there with robots having the ability to do intelligent tasks like autonomous navigation. The future will see smarter robots that can perform more sophisticated tasks with the help of new-age cameras and better AI models. Here are some of the trends that are likely to define the future of construction robots and drones:

Infographic on future trends in construction robots

- Performing skilled labor: Robots will be able to perform skilled labor such as mechanical repair or interior décor.

- Fully autonomous drones: Drones could possess the ability to determine what type of images to capture by going on a flight autonomously.

- Autonomous vehicles for transport: Today, materials are transported with the help of manually driven vehicles in large construction sites. The future could see autonomous vehicles or goods-to-person robots (like the ones used in warehouses) taking over this.

- A higher number of cameras: With advancements in processing platforms, the number of cameras used in robots is likely to increase in an attempt to improve accuracy.

How TechNexion contributes to a smarter and sustainable future

The integration of vision and AI into robotics certainly contributes to a smarter and more sustainable future. TechNexion aims to be one of the frontrunners in this evolution by building end-to-end solutions for robots including cameras and system on modules. From global shutter cameras to FPD-Link cameras and NIR cameras, our portfolio has everything your robot needs when it comes to imaging.

TechNexion also develops system on modules that come with comprehensive features required for robots such as video and AI acceleration, diverse I/O options, and a ready-to-go software, all at an affordable cost. The EDM-IMX95, an NXP i.MX95-based system on module, is a great example of this.

Talk to a TechNexion expert today to learn how our products and solutions can accelerate your robot development journey.

Related Products

- Understanding key challenges in the construction industry

- How robots and drones can help address these challenges?

- Promoting sustainability in construction with robotics

- The role of cameras and AI in the robotic revolution

- The future of vision and AI-enabled robotics in construction

- How TechNexion contributes to a smarter and sustainable future

- Related Products

Get a Quote

Fill out the details below and one of our representatives will contact you shortly.