The fourth industrial revolution has transformed industries by integrating advanced technologies. From Artificial Intelligence to IoT (Internet of Things), automation to big data analytics, it has given rise to various smart factory concepts and advancements, improving plant efficiency, increasing production stability, and minimizing operations costs.

Integrating embedded cameras in Industry 4.0 processes has sparked another revolution beyond their traditional use of detecting errors. Today, it is used in diverse areas such as predictive maintenance, navigation of AMRs (Autonomous Mobile Robots), and surveillance across various industrial settings.

Here are a few things Embedded Cameras help industrial automation systems with:

- Automate visual inspections of products on production lines, ensuring quality standards, and reducing manual inspection errors.

- Be the ‘eyes’ of robots to track and analyze real-time data and streamline warehouse and factory processes.

- Automate inventory management, tracking, picking, and movement optimization tasks by leveraging ML (Machine Learning) and computer vision algorithms.

- Contribute to safety with smart surveillance and security solutions to detect potential threats within restricted areas.

Among the many types of embedded cameras, FPD-Link III cameras have proved to be a great fit for a vast majority of industrial imaging applications. In this article, we provide an understanding on how FPD-Link III cameras contribute to Industry 4.0 by becoming a key component of industrial vision systems.

We will talk about:

- What FPD-Link III cameras are.

- Key features and applications of FPD-Link III cameras in the industrial sector.

- Advantages of FPD-Link III cameras in industrial imaging.

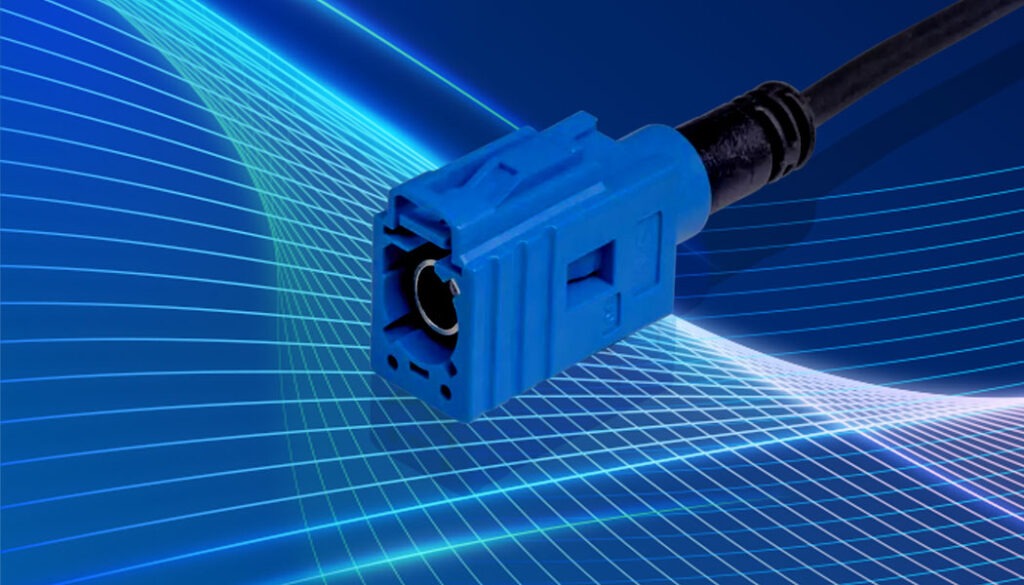

FPD-Link III Connector

What is an FPD-Link III Camera?

The FPD-Link III (Flat Panel Display Link III) is an interface used in automotive and industrial applications to transfer data from one point to another using the SerDes methodology. FPD-Link III is known for its high-speed data transmission between the camera module and the processor. It is a full duplex interface that ensures the data conversion process happens in both directions at the same time.

FPD-Link III works by serializing the camera sensor interface (usually MIPI-CSI2) over a single high-speed signal pair. This is then deserialized, converting it back into MIPI-CSI2, to stream the video data to the host processor. FPD-Link III also provides for communications in the opposite direction so that the host processor can manage the camera sensor as if it were directly attached to it.

Power to the camera is easily transmitted over the same signal pair, or in most cases, a single coax cable, making this one of the simplest and most robust camera connection interfaces available.

The interface is designed to withstand heavy shocks and vibrations that meet the requirements of even the most sophisticated industrial vision systems, making it a reliable and one of the most popular SerDes (serializer/deserializer) camera interfaces.

Simply put, FPD-Link III cameras help transmit image data over a long distance with high quality and the lowest latency.

Key Features of FPD-Link III Cameras

Let us look at some of the most important features of FPD-Link III cameras:

1. Long Distance High Bandwidth Transmission

Other popular camera interfaces like MIPI and USB have limitations when it comes to the distance of transmission. While the former can take data only up to a distance of 30cm, the latter has a maximum distance of transmission of 3m (depending on the cable and whether it is USB2.0 or USB3+).

In contrast, the FPD-Link III interface can transmit image and video data up to 15 meters without compromising data integrity. This is a blessing in industrial automation systems where often the camera must be placed several meters away from the processor. FPD-Link III cameras offer high speed transmission with a maximum bandwidth of 4 Gbps, allowing for 2 Mp sensors to be connected at full framerate of 60 fps.

2. Low Latency

Latency refers to the time measured or the delay to capture the image or video by a camera and display it on the screen.

A high latency is acceptable for streaming recorded events; however, latency cannot be compromised in industrial applications. It’s especially important for devices that need to make informed decisions by processing the data in real-time.

As FPD-Link III serializes, and does store or reformat the camera data stream, the added latency is very minimal, in the order of microseconds.

FPD-LINK III cameras offer a low latency rate with a single twisted pair or coax cable, minimizing the data transmission delays. That helps in real-time monitoring in systems such as robots and autonomous vehicles.

3. Industrial grade with the ability to resist shocks and vibrations

In automotive and industrial environments, embedded cameras are exposed to challenging conditions such as temperature, humidity, vibrations, and shocks.

FPD-Link III cameras have robust mechanical features – offering enhanced resistance to shocks, vibrations, and other challenges when working in extreme industrial conditions, which ensures the embedded camera remains reliable and functions evenly to transfer data without delays and interruptions.

Applications of FPD-Link III Cameras

FPD-LINK III cameras enable high data transmission between the camera and the processor, making it one of the best solutions for industrial applications. Here are a few notable applications where FPD-Link III cameras would be a great fit.

1. Robotics

Robots have numerous industrial applications – from warehouse inventory management to quality inspection and streamlining processes. Robots integrated with FPD-Link III cameras can significantly enhance their performance, communication, and integration with automation systems.

Here are a few applications of embedded cameras with different industrial robots:

- Pick and Place Robots: These robots pick and place objects on the warehouse shelves with precision. A combination of 2D and 3D cameras is used here for locating and placing the objects in the right place.

- Goods-to-person Robot: These automated robotic vehicles use cameras to locate items in the warehouse, streamline order fulfillment, and precisely navigate the warehouse environment.

- Inventory Tracking Robots: These automated robots manage and monitor inventory in the warehouse. They utilize embedded cameras to identify objects with barcode/RFID tags and collect the required data. Often, inventory tracking is not done using a dedicated robot. The function is rather integrated into a multi-purpose warehouse robot (like a goods-to-person robot for example).

- Large Robotic Arms: Robotic arms automate tedious, complex, or dangerous tasks, like picking heavy products from one place and placing them in another. The cameras help robotic arms detect, identify, and locate objects to place at the desired location.

- Picking and Sorting Robots: With high-volume manufacturing, quickly and accurately placing the objects onto the conveyor belts and automating sorting is complex. Using cameras helps robots achieve this by swiftly determining the depth and nature of the objects.

Warehouse robots

FPD-Link III cameras are suited for robotic applications owing to features such as long-distance transmission, high bandwidth, and industrial grade build.

2. Automated Forklifts

An automated forklift is a type of AMR that transports heavy loads across a warehouse without requiring manual work. These forklifts handle equipment used in warehouses, production centers, and other industrial environments.

Embedded cameras help automated forklifts to work independently and more productively. Automated forklifts use camera modules to measure the dimensions of the object to lift, adjust the forks automatically, and verify items before picking/delivering without the need for any manual control. FPD-Link III cameras are perfectly suited for an application like this.

3. Mining Trucks

Large mining trucks tend to have blind spots and limited visibility, which makes it difficult for the operators to see obstacles and other vehicles. These vehicles are often 50 feet long and carry tons of materials, increasing the risk of operator and truck damage.

Embedded cameras limit the risk by ensuring operators’ safety, collisions, and rollovers using multiple FPD-LINK III cameras for surround view. The use of multiple cameras and high frame rate imaging eliminate the risk of blind spots as these work synchronously, providing a stitched view of the surroundings.

A large mining truck

4. Perimeter Security System

Perimeter security is becoming a major concern with the increase in security breaches. Most industrial areas are large, which makes manually monitoring and securing them challenging. This is where systems like patrol robots, drones, and surveillance cameras help by acting as an efficient and cost-effective way of accurately detecting thefts and intrusions.

Drones offer unique advantages in monitoring large areas, by reaching inaccessible areas without risking the safety of the security personnel. They can quickly cover larger spaces, from warehouses to mines, and capture high-resolution images and videos to detect any potential threats or suspicious activities within the perimeter.

Patrol robots integrated with FPD-Link III cameras and AI capabilities can automatically patrol designated areas of the industrial perimeter to identify potential threats. These robots can cover large areas 24/7, enabling monitoring, capturing live feeds, and sharing real-time data with security personnel.

Advantages of using FPD-LINK III cameras in Industrial Applications

FPD-Link III cameras offer the following advantages for industrial vision systems:

- Suitable for Large Industrial Vehicles: They can connect cameras as far as 15 meters from the processing system without compromising performance, latency, and signal integrity. This makes them suitable for use in large industrial vehicles.

- Power and Data over the Same Cable: FPD-LINK III cameras can transmit video, power, and data over the same cable.

- Durability: FPD-LINK III cameras are designed to operate in harsh industrial conditions, such as dust, heat, shock, mechanical vibrations, and electromagnetic interferences that affect performance. For instance, TechNexion’s FPD-Link III cameras come with the FAKRA connector that makes them suitable for use in any industrial equipment.

- High-Speed Data Transmission: Regarding bandwidth, FPD-Link III offers a maximum bandwidth of up to 4 Gbps and beyond, enabling high-speed data transmission with Shielded Twisted Pair, Shielded Twisted Quad, or Coax cables.

- Real-time Decision Making: FPD-Link III cameras offer high-quality video in real-time with a low latency rate, making them suitable for surveillance, monitoring, and timely control of the navigation of AMRs.

FPD-Link III Aluminium Enclosed Camera with onsemi AR0521 5MP Rolling Shutter with Onboard ISP + S-mount Lens with IR-Cut Filter

VLS-FPD3-AR0521-SL

- onsemi AR0521 5MP Rolling Shutter Sensor

- Designed for Low Light Applications

- S-Mount for Interchangeable Lenses

- FAKRA Z-Code Automotive Connector

- Plug & Play with Linux OS & Yocto

- VizionViewer™ configuration utility

- VizionSDK for custom development

How can TechNexion’s FPD-Link III Cameras Help?

TechNexion’s FPD-Link III cameras are IP68-rated and transmit data with 15-meter extension cables using FAKRA connectors. Some of the other features of our FPD-Link III camera portfolio include:

- Rolling shutter and global shutter variants

- Near IR enhancement

- High resolution (up to 13 MP)

- High dynamic range

- S mount and C mount

Check out our FPD-LINK III solutions here.