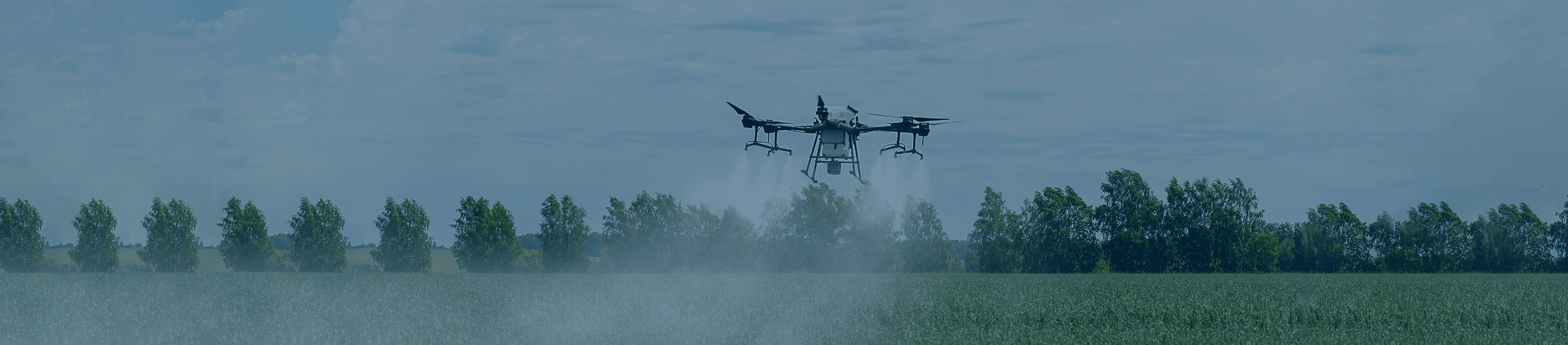

Drones are all around us nowadays. They’re used for things like making videos, inspecting big machines, and even delivering packages. But did you know that the type of camera you put on a drone can make a big difference in how well it works?

You might already know that cameras are like the eyes of a drone. They take pictures and videos while the drone is flying. They also help the drone figure out where to go and avoid crashing into things. One tricky thing drones have to do is take clear pictures when they’re moving fast. Sometimes, regular cameras can make the pictures blurry when the drone is flying quickly.

That’s where a special kind of camera technology called global shutter comes in handy. Global shutter cameras can take pictures and videos without artifacts, even when the drone is in fast motion. In this blog post, we will learn how global shutter cameras can help achieve better imaging in drones used across various applications including agriculture, construction & mining, industrial inspection, etc.

Rolling Shutter Cameras vs. Global Shutter Cameras

We’re about to learn how global shutter cameras are making drones work better.

But before we do that, let’s understand the difference between the two types of cameras based on shutter type: rolling shutter and global shutter.

Rolling shutter cameras take pictures by reading the image line by line, like how you read a page from top to bottom.

This can make the output image look distorted if things move too fast during capture.

Take a look at the video to see how a rolling shutter works:

Now let’s come to global shutter.

Global shutter cameras, unlike rolling shutter cameras, capture a scene in one go – meaning that they read out the image all at once instead of doing it line by line. Have a look at the below illustration to understand this concept better:

This mechanism makes sure that the output image is free of any distortions or artifacts. A global shutter camera is preferred in applications where either the object or the embedded vision device is moving fast.

How Do Global Shutter Cameras Help Drones?

Imagine an agricultural drone used for capturing images of farmland for crop monitoring. The drone must do this as it moves and flies above the land. Considering that the average speed of the drone can vary between 30 to 100 km/h, the image capture must happen faster than the blink of an eye.

A global shutter camera is a game-changer in this scenario as it can read out the entire scene at the same time.

The camera is usually fitted at the bottom end of the drone facing downward to get a complete view of the farmland. Often, to cover the entire field of view, multiple cameras might have to be used.

The use of a multi-camera system can also help avoid lens distortion or vignetting.

Why is Frame Rate Important?

While global shutter cameras help to avoid artifacts, owing to the fast motion of drones, a low frame rate of 10 or 15 fps (or even 30 fps) might not suffice to capture images at the required speed. For this reason, it is recommended that the camera comes with a minimum frame rate of 60 fps. However, in most cases, a frame rate over 120 fps might be required.

Another factor to consider is how the camera is being used. For example, if the camera is being used for collision avoidance, then the frames from the camera must be processed at a rate that would allow the drone to avoid detected obstacles within the relevant timeframe. Depending on how fast the vehicle moves at the time, this could be quite important.

Other Drone Applications of Global Shutter Cameras

We understood how cameras are used in agricultural drones. In this section, let us learn more about some of the other applications of drones where global shutter cameras are recommended.

Warehouse Inspection and Inventory Management

Warehouse drones are used for multiple purposes such as:

- Tracking the inventory on warehouse shelves

- Transporting materials from one point to another within the warehouse

- For inspection or patrolling

For all these tasks, drones must take images of people and objects while they (both the drone and potentially the people and objects) are in motion. Global shutter cameras are perfect in such a scenario. Since warehouse drones tend to move slower compared to agricultural drones so the frame rate might not have to be as high. However, this needs to be determined on a case-by-case basis.

Delivery Drones

Delivery drones are not as common in use as some of the other examples we are discussing today owing to policy challenges and safety concerns. However, many cities and technology companies around the world are experimenting with it. Retail giant Walmart, for example, is currently building a delivery drone system with Google subsidiary, Wing.

As the name suggests, delivery drones are used for last-mile delivery services. They use multiple cameras to stay away from obstacles (such as people, pets, buildings, etc.) in the air as well as the ground. Global shutter cameras can help them identify objects based on their physical characteristics. For example, the drone has to take better safety measures when it has a human obstacle compared to an object, in which case the accuracy of object recognition becomes critical. This means that the images captured shouldn’t have artifacts in them at any cost.

Construction and Mining Sites

Drones are used in construction and mining sites primarily for inspection and surveillance. In large construction sites, physically inspecting every nook and corner is time-consuming and labor-intensive. Hence, drones are used to automate this and conduct inspections at scale.

When it comes to mines and refineries, the safety of workers is of utmost importance. For this reason, drones are used for preliminary inspections in the event of any leakage or damage. Drones also help to reach areas that are not easily accessible by humans.

Depending on the nature of the inspection, a global shutter camera might or might not be required in a drone used in construction sites and mines. This is because inspections are usually carried out at specific points or locations. Image capture typically happens at that location, and the drone is mostly static when it happens.

At the same time, if an entire site has to be covered on the move, it is recommended to use a global shutter camera.

One aspect of drones being used for indoor and mining applications is that they cannot rely on GPS for positional navigation. In these cases, the drone must localize itself (locate itself within a digital map of the terrain), and cameras are one vital way in which drones can do this, by using visual points of reference determined from live video feeds.

Factories

As in the case of mines, drones are used in factories for inspection. These usually are compact drones that can inspect the interiors of pipes and turbines that are not accessible by humans. Global shutter cameras are needed in such use cases, especially if it involves the inspection of say a fast-moving shaft.

Closing Words

A ‘one size fits all’ approach never works in camera selection. Though global shutter cameras help in eliminating artifacts, it doesn’t necessarily mean that every drone needs one. The purpose of the camera also matters a lot here.

For instance, a camera facing downward in an agricultural or warehouse drone mostly will need the global shutter mechanism. Whereas a camera used in the same drone for obstacle detection may find a rolling shutter camera more suitable. Depending on the complexity of the use case, a LiDAR-based system could also be used for obstacle detection instead of an embedded camera.

In essence, a best practice is to treat every use case differently. You can always feel free to take the help of TechNexion’s camera engineers before choosing a camera for your drone.

TechNexion: Helping Engineers Build the Drones of Tomorrow

Drones have revolutionized the AGV (Automated Guided Vehicle) space. They have become mainstream now. Despite this transformation, engineers building drones continue to face imaging-related challenges during development. This is primarily because the technical know-how in cameras and imaging doesn’t come easy, and it usually takes an expert to solve complex problems in camera modules.

This is where TechNexion has been able to make a notable difference in the past few years. We have worked with multiple drone manufacturers globally and helped them seamlessly integrate our cameras into their drones. This has given us firsthand experience working on practical challenges associated with embedding cameras into these little flying machines.

From ensuring you pick the right camera to integrate it with sensors like GPS and IMU, we can help you with the end-to-end spectrum of your imaging needs.

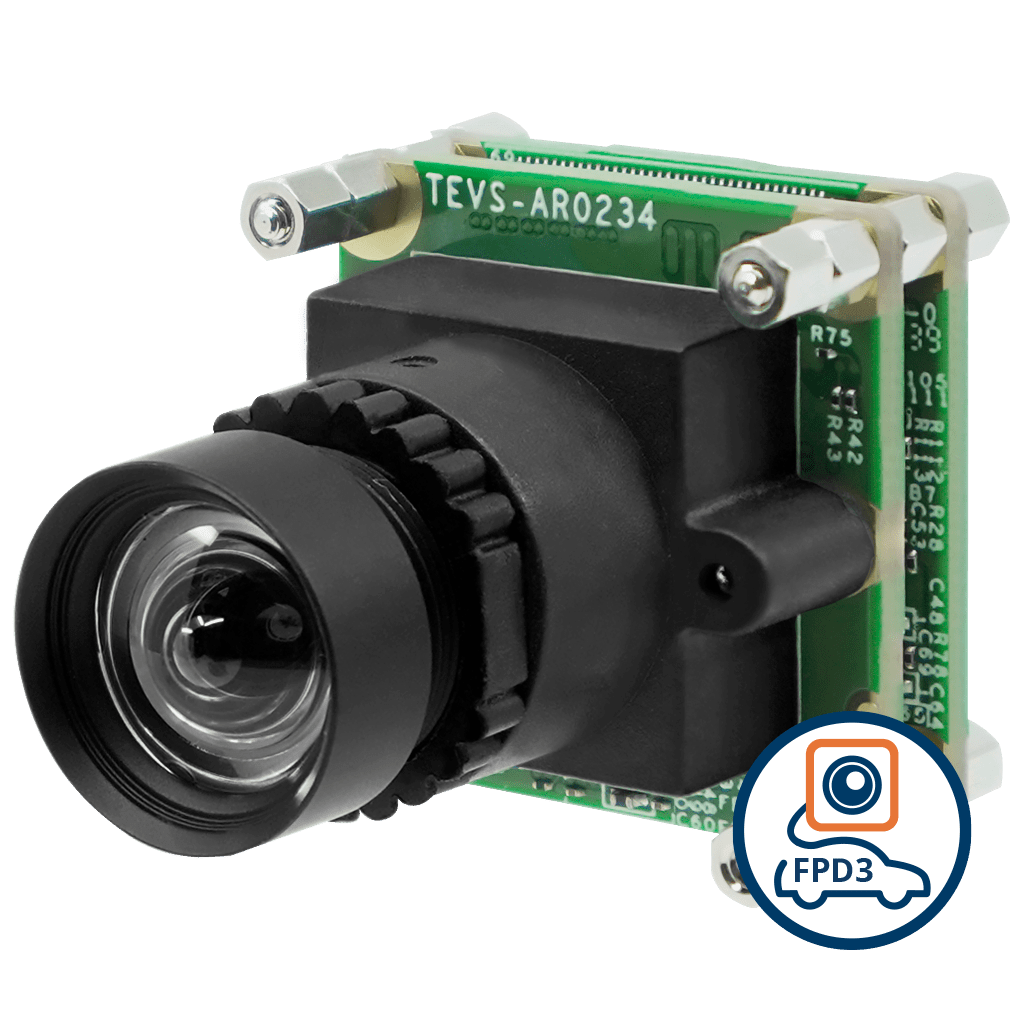

Our experience of two decades in the embedded industry coupled with a state-of-the-art manufacturing facility has helped us deliver world-class camera solutions to all our customers. We offer global shutter cameras based on the AR0144 and AR0234 sensors with USB and platform versions. They also come with both S-mount and C-mount lens options. Learn more about our embedded vision products here. You could also watch the video to understand their key features and configurations.

Related Products

- Rolling Shutter Cameras vs. Global Shutter Cameras

- How Do Global Shutter Cameras Help Drones?

- Why is Frame Rate Important?

- Other Drone Applications of Global Shutter Cameras

- Warehouse Inspection and Inventory Management

- Delivery Drones

- Construction and Mining Sites

- Factories

- Closing Words

- TechNexion: Helping Engineers Build the Drones of Tomorrow

- Related Products

Get a Quote

Fill out the details below and one of our representatives will contact you shortly.