Don’t want to scare you right away, but here are a few alarming statistics to pay attention to:

- Unplanned downtime costs industrial manufacturers as much as $50 billion annually.

- 82% of companies have experienced at least one unplanned downtime incident in the last few years.

- Downtime can reduce 1%-10% of available production time.

Now that we’ve set the stage, let’s break down the cause: many factories still depend on traditional reactive, run-to-failure maintenance strategies. In other words, they only fix equipment after it breaks down, rather than addressing potential issues beforehand. Sounds like you?

Well, that’s where modern technological solutions like Edge AI and smart cameras come in. By enabling real-time monitoring, predictive maintenance, and instant decision-making without relying on the cloud, Edge AI and smart camera solutions reduce downtime, boost efficiency, and keep production lines running smoothly.

In this blog post, we’ll explore how Edge AI-powered smart cameras are transforming industrial automation and ensuring that costly disruptions become a thing of the past.

Understanding Downtime and Its Impact

Downtime refers to any period when equipment, machinery, or production systems are unavailable, either due to unexpected failures (unplanned downtime) or scheduled maintenance (planned downtime). While planned downtime is necessary for system upkeep, unplanned disruptions can be catastrophic for industrial operations.

The impact? Lost production time, supply chain delays, increased operational costs, and missed revenue opportunities. Beyond financial losses, downtime can also affect product quality, lead to worker idle time, and damage customer relationships.

Understanding Edge AI and Smart Cameras

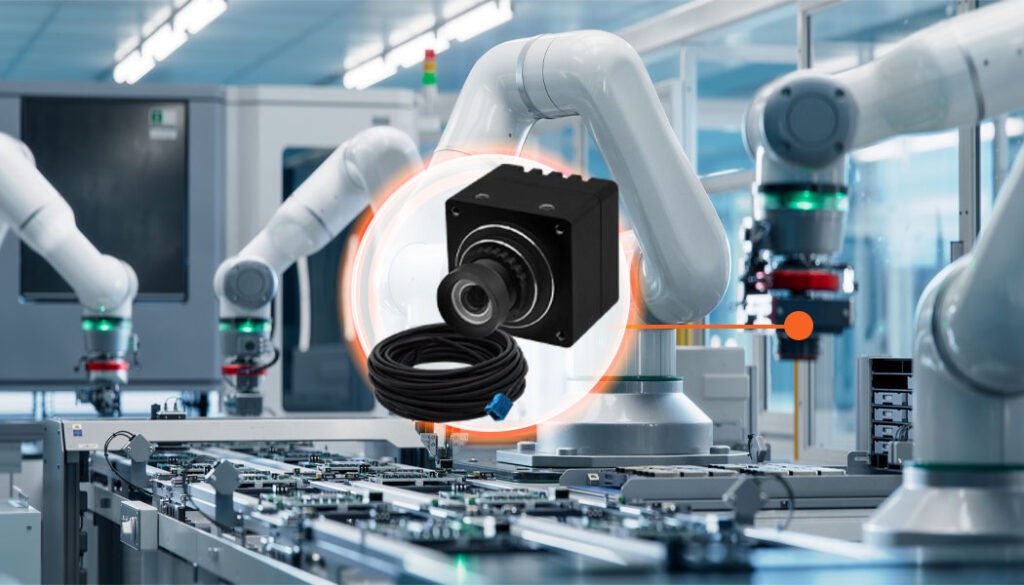

Smart Industrial Camera

What is Edge AI? Unlike traditional AI systems that rely on cloud servers for data processing, Edge AI processes data directly on local devices. This means that instead of sending large volumes of sensor or video data to remote servers, computations happen on the edge: Right where the data is generated. This approach significantly reduces latency, bandwidth usage, and dependence on internet connectivity.

Smart cameras are a prime example of Edge AI in action. These AI-powered vision systems analyze visual data in real time, detecting anomalies, tracking movement, and identifying patterns without needing to transmit footage to external servers. In industrial environments, this means machines can be monitored continuously and autonomously, helping detect failures before they escalate into costly downtime.

Processing data locally has major advantages. Low latency ensures instant decision-making, bandwidth efficiency reduces the strain on network infrastructure, and real-time insights enable proactive maintenance. Manufacturers can transition from reactive fixes to predictive solutions by integrating Edge AI-driven smart cameras. This ultimately helps improve efficiency, reduce costs, and boost overall equipment effectiveness (OEE).

Causes of Downtime in Industrial Environments

Downtime in manufacturing can stem from various factors, each impacting productivity, efficiency, and profitability. While some issues are unavoidable, many can be mitigated with the right technology. Here are the most common causes:

- Machine Failures

Unexpected equipment breakdowns account for a significant share of unplanned downtime. Aging machinery, lack of preventive maintenance, and overheating components can halt production for hours or even days.

- Quality Control Issues

Defective products can lead to production stoppages, as manufacturers need to recalibrate machines, rework defective items, or discard faulty batches. Poor-quality raw materials and calibration errors contribute to this issue.

- Human Error

According to research, human error is responsible for nearly 23% of unplanned downtime in manufacturing. Mistakes in machine operation, incorrect material handling, and improper equipment setup can all disrupt production lines.

- Supply Chain Bottlenecks

Delays in material delivery, mismanaged inventory, or supplier disruptions can slow down production, leaving machines idle and affecting overall output.

- Software or System Failures

Outdated control systems, connectivity issues, and software glitches can bring industrial operations to a standstill, requiring troubleshooting and repairs.

Manufacturers can significantly reduce downtime and improve operational efficiency by addressing these challenges with predictive maintenance and automation.

How Edge AI Smart Cameras Reduce Downtime

Edge AI smart cameras are transforming how manufacturers approach downtime reduction by providing real-time insights and predictive capabilities.

Predictive Maintenance

Smart cameras equipped with Edge AI capabilities can analyze machine performance through various means. For example, vibration analysis and thermal imaging. With continuous equipment monitoring capabilities, these cameras can detect subtle changes that may indicate potential failures.

For instance, if a machine shows unusual vibration patterns or excessive heat, the system can alert maintenance teams before a complete breakdown occurs. This real-time anomaly detection enables early failure prediction. This allows manufacturers to schedule maintenance proactively, significantly reducing the risk of unplanned downtime.

Quality Inspection & Defect Detection

Quality control is another area where Edge AI smart cameras shine. Traditional manual inspection processes can be slow and prone to human error, leading to defects slipping through the cracks. AI-driven visual inspection technology allows smart cameras to identify defects with high accuracy and speed.

Using advanced image processing algorithms, these cameras can quickly scan products on the production line, flagging any issues for immediate attention. This not only reduces the likelihood of defective products reaching customers but also streamlines the production process, increasing overall efficiency.

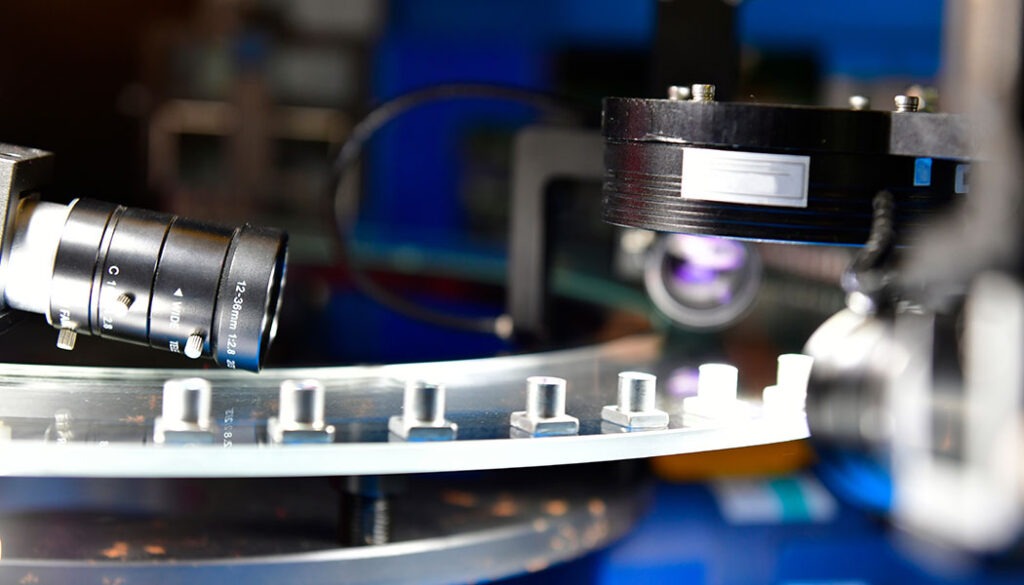

Quality inspection camera

Worker Safety & Compliance Monitoring

Ensuring worker safety is paramount in any industrial environment. Edge AI smart cameras can play a vital role in detecting hazardous situations and enforcing safety protocols. For example, these cameras can monitor areas where employees are working with heavy machinery, identifying any unsafe practices or behaviors.

Additionally, they can verify compliance with Standard Operating Procedures (SOPs), ensuring that workers adhere to safety guidelines. Manufacturers can reduce the risk of accidents and subsequent downtime by enhancing safety measures. This helps in fostering a more secure work environment.

Process Optimization & Workflow Automation

Edge AI smart cameras also contribute to process optimization and workflow automation. With production line data analyzation being done in real time, these cameras can provide insights into operational inefficiencies. For example, if a specific machine consistently slows down production, the system can highlight this bottleneck, enabling managers to take corrective action.

AI-driven insights allow manufacturers to optimize their processes continuously, ensuring that production lines operate smoothly and efficiently. By identifying and addressing inefficiencies, businesses can minimize downtime and maximize output.

Key Technologies Powering Edge AI Smart Cameras

The overall effectiveness of Edge AI smart cameras in industrial automation relies on a combination of advanced technologies. These include:

AI Algorithms for Industrial Vision

At the core of Edge AI and smart cameras are sophisticated AI models designed for industrial applications. Convolutional Neural Networks (CNNs) are widely used for image recognition. They enable cameras to identify defects, classify objects, and monitor production lines with high accuracy.

Additionally, anomaly detection algorithms analyze deviations in machine behavior, helping predict failures before they occur. Deep learning techniques enhance these capabilities, continuously improving defect detection and predictive maintenance through training on vast datasets.

Edge AI-enabled smart camera

Edge Computing Hardware

To process AI models efficiently, Edge AI smart cameras incorporate specialized hardware optimized for real-time data processing. AI accelerators like NVIDIA Jetson, Intel Movidius, and Google Coral power these cameras. They enable the cameras to run deep learning models without requiring cloud-based resources.

Industrial-grade smart cameras are equipped with dedicated processors and neural network accelerators, allowing them to handle AI workloads locally. This results in lower latency, reduced bandwidth usage, and improved security. As you know, this is because sensitive data never needs to leave the premises.

IoT and Connectivity

Smart cameras in industrial environments don’t function in isolation. They integrate seamlessly with Industrial IoT (IIoT) systems to provide real-time insights across entire production lines. Connectivity technologies like 5G and edge-to-cloud communication enhance the efficiency of AI-powered automation by ensuring ultra-fast data transmission and remote monitoring capabilities.

By integrating AI-driven vision systems with IIoT networks, manufacturers can optimize operations and improve overall efficiency. This connection enables predictive insights, allowing issues to be detected and resolved before they cause downtime, ensuring seamless industrial workflows.

Challenges and Considerations

While Edge AI smart cameras offer significant advantages, they also come with challenges that warrant attention

- Data Privacy and Security

Processing sensitive industrial data locally reduces cloud exposure, but security risks remain. Unauthorized access, data breaches, and cyber threats must be addressed with strong encryption and access controls.

- Hardware Limitations

Edge AI devices rely on compact processors with limited computational power. Running complex AI models on low-power hardware can be challenging, requiring efficient model optimization and specialized accelerators.

- Integration with Existing Systems

Many factories use legacy automation systems that weren’t designed for AI integration. Ensuring compatibility between smart cameras, industrial robots, and control systems requires careful planning and investment.

Despite these challenges, advancements in AI hardware, cybersecurity, and industrial IoT connectivity are steadily overcoming these limitations. With the right implementation, Edge AI smart cameras can revolutionize industrial automation while maintaining security and efficiency.

Future of Edge AI in Industrial Automation

While Edge AI smart cameras offer significant advantages, they also come with challenges that warrant attention

- Data Privacy and Security

Processing sensitive industrial data locally reduces cloud exposure, but security risks remain. Unauthorized access, data breaches, and cyber threats must be addressed with strong encryption and access controls.

- Hardware Limitations

Edge AI devices rely on compact processors with limited computational power. Running complex AI models on low-power hardware can be challenging, requiring efficient model optimization and specialized accelerators.

- Integration with Existing Systems

Many factories use legacy automation systems that weren’t designed for AI integration. Ensuring compatibility between smart cameras, industrial robots, and control systems requires careful planning and investment.

Despite these challenges, advancements in AI hardware, cybersecurity, and industrial IoT connectivity are steadily overcoming these limitations. With the right implementation, Edge AI smart cameras can revolutionize industrial automation while maintaining security and efficiency.

AI Algorithms for Industrial Vision

At the core of Edge AI and smart cameras are sophisticated AI models designed for industrial applications. Convolutional Neural Networks (CNNs) are widely used for image recognition. They enable cameras to identify defects, classify objects, and monitor production lines with high accuracy.

Additionally, anomaly detection algorithms analyze deviations in machine behavior, helping predict failures before they occur. Deep learning techniques enhance these capabilities, continuously improving defect detection and predictive maintenance through training on vast datasets.

Edge AI-enabled smart camera

Wrapping Up

Edge AI-powered smart cameras are transforming industrial automation by minimizing downtime through predictive maintenance, real-time quality inspection, and workflow optimization. As industries seek AI-driven automation for long-term ROI, adopting these solutions has become essential.

TechNexion drives edge AI innovation with embedded computing solutions for industrial automation. NVIDIA Jetson-based solutions based on processors like Orin NX and AGX Orin offer scalable AI for manufacturing, security, and automation.

Ready to enhance your industrial operations with edge AI? Contact TechNexion today!

Related Products

- Understanding Downtime and Its Impact

- Understanding Edge AI and Smart Cameras

- Causes of Downtime in Industrial Environments

- How Edge AI Smart Cameras Reduce Downtime

- Key Technologies Powering Edge AI Smart Cameras

- Challenges and Considerations

- Future of Edge AI in Industrial Automation

- Wrapping Up

- Related Products

Get a Quote

Fill out the details below and one of our representatives will contact you shortly.