One of the biggest revolutions brought about by embedded vision is the ability to build compact imaging systems. While machine vision cameras helped automate various tasks in the industrial sector, they were not built to be compact. Instead, they were often bulky and required specialized industrial PCs to run the processing tasks.

In addition, there were limited on-device processing capabilities. Complex processing had to be done using cloud-based software, which added to the TCO (Total Cost of Ownership). Embedded vision solved both problems with enhanced on-device processing capabilities. That made it possible to build small form factor devices integrated with imaging capabilities.

In this blog post, we dive deep into how embedded cameras are helping build high-performance compact embedded vision systems.

What are compact embedded vision systems?

There is no standard definition as to what is ‘compact.’ Size is always relative. If you are able to perform a task using a new technology or innovation with a much smaller and easy-to-handle device, it can be called compact.

For example, earlier in factory automation, machine vision cameras were used on a conveyor belt to capture images & videos and send them to a host PC for processing. However, with the advent of embedded vision, this processing can be carried out on the device itself using high-end processors like NXP i.MX95, NVIDIA Jetson, or TI Jacinto TDA4VM. This results in a much smaller device with optimized space utilization and reduced cost owing to fewer components.

Compact camera modules – technological evolution

Compact camera modules, which are the heart of an embedded vision system, were developed as a result of multiple technological advancements. The first one of them is the rapid developments in sensor technology.

The sensors used in the past for industrial, medical, and scientific applications were mostly CCDs (Charge Coupled Device). While these were excellent when it came to sensitivity, they were relatively larger in size. Modern embedded cameras leverage CMOS (Complementary Metal-Oxide Semiconductor) sensors that are smaller in size but are able to deliver almost the same quality as CCD sensors. This helped product developers build more compact vision systems while still achieving the same levels of performance.

Another key development in the space that enabled compact designs is the invention of processing platforms that can deliver superior performance with a small form factor. The NXP i.MX series of processors is a great example.

In addition to these technological shifts, other components of a camera system such as lenses, interfaces & connectors, ISPs (Image Signal Processors), etc., also improved in performance, heat resistance, and durability. This in turn fueled the growth of small form factor embedded vision systems.

Now, what is a compact camera module?

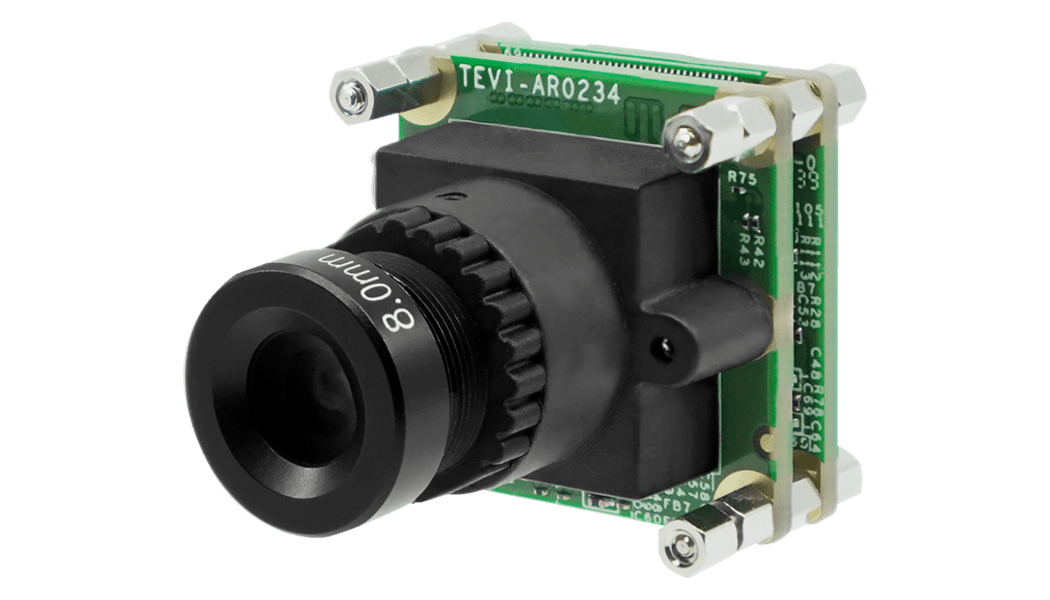

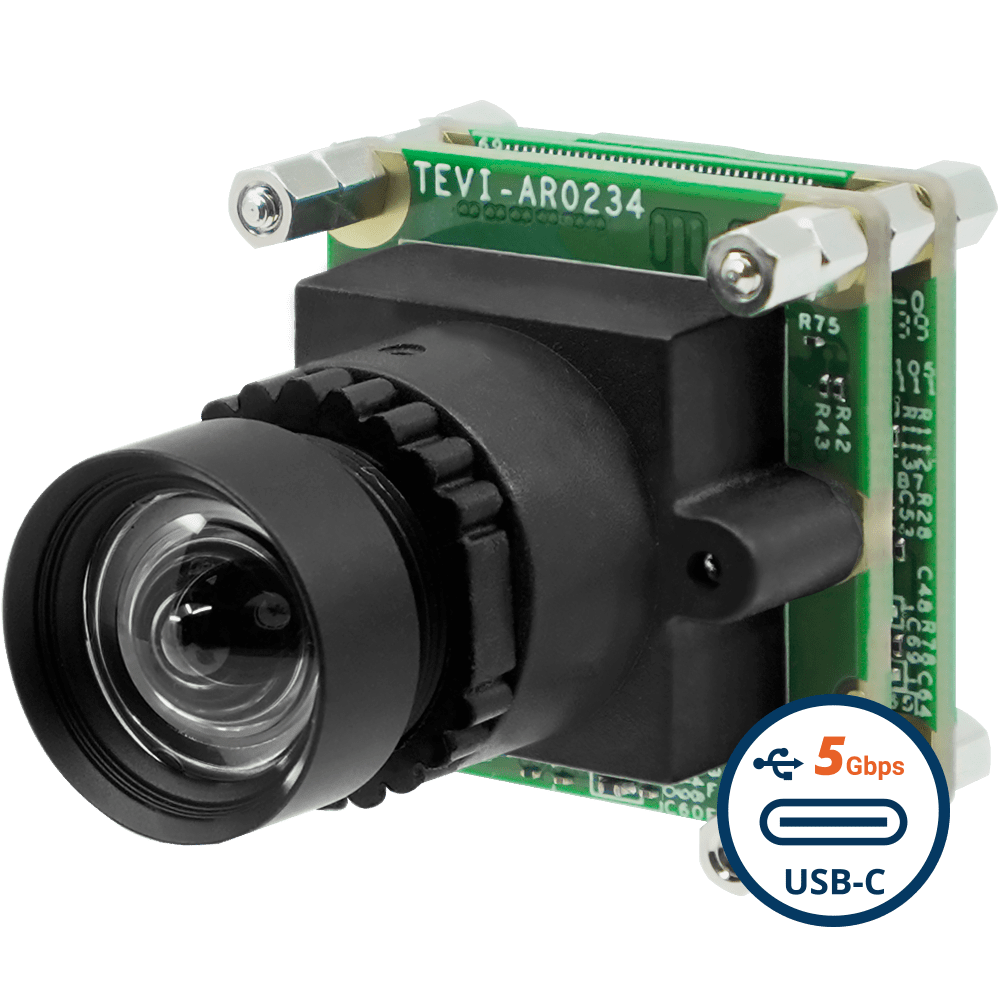

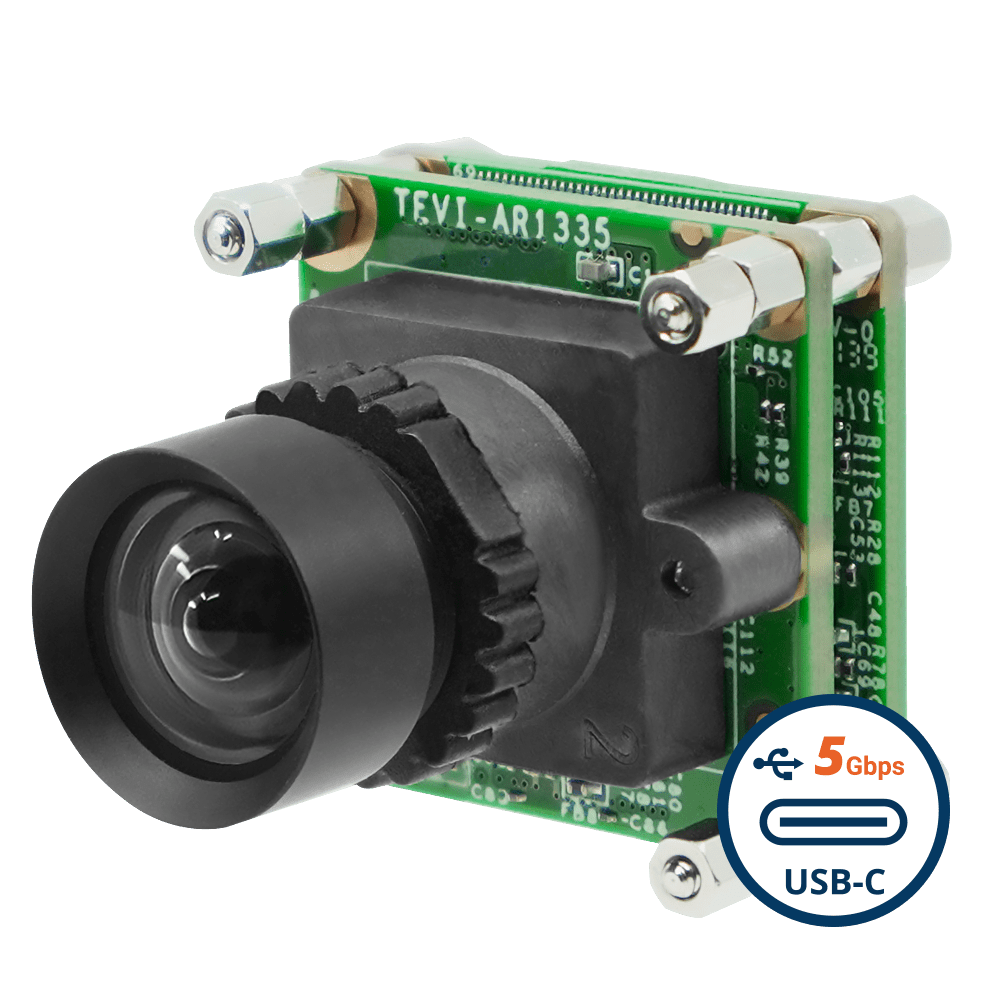

Again, there is no standard definition as to what a compact camera is. But, typically, a module within the dimensions of 40mm x 40mm can be considered compact. For instance, UVCI-AR0234-SL, an AR0234 global shutter USB camera from TechNexion, comes with the dimensions of 24.5(W) x 24.5(H) x 25.6(D) mm. This can be considered a compact camera. TechNexion’s camera portfolio has several other products that come with similar dimensions.

Types of compact camera modules

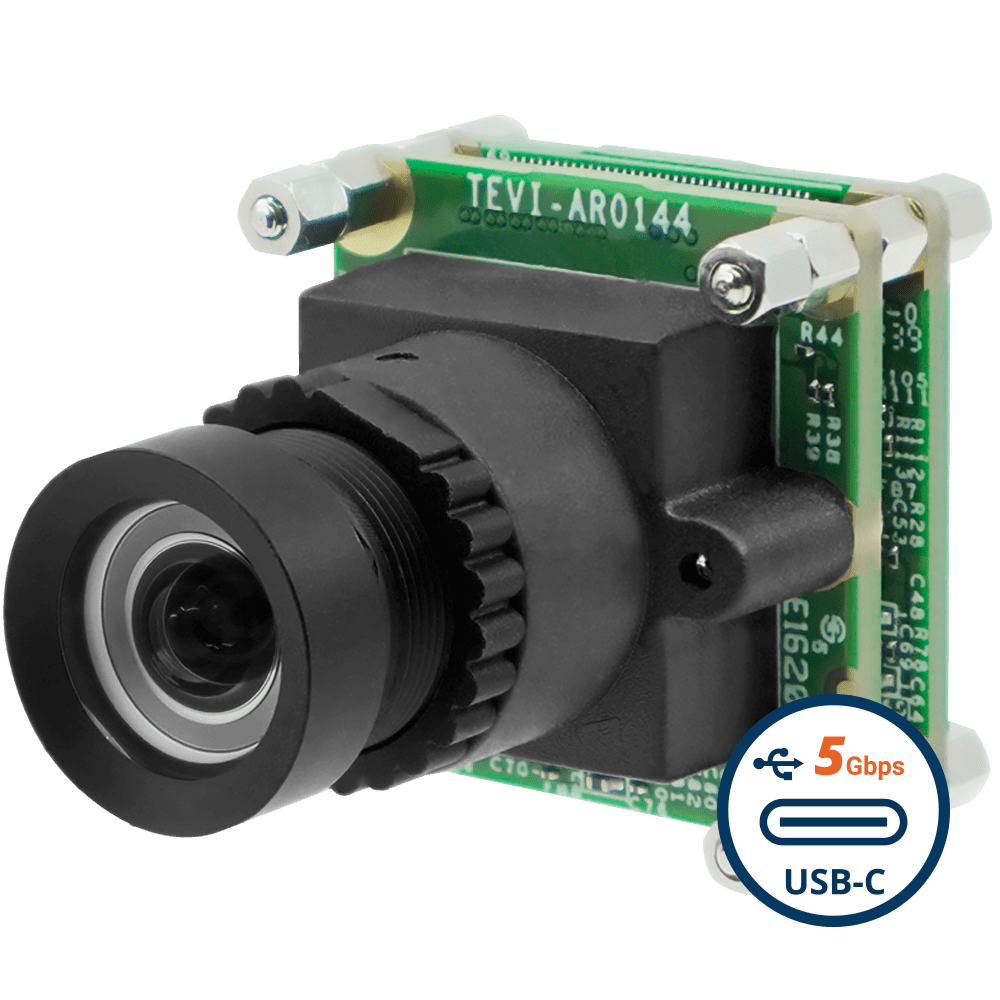

Camera modules are of many types. Depending on the parameter you consider, the classification will differ. One of the most common parameters used for categorizing embedded cameras is interface. Following are the camera types in embedded vision based on the interface used:

- USB UVC cameras – Use the USB protocol to connect the camera to the host.

- MIPI cameras – Use MIPI as the interface between the camera and the processor.

- FPD-Link cameras – FPD-Link is a SerDes interface designed by Texas Instruments.

- GMSL cameras – GMSL cameras use the GMSL interface originally from Maxim Integrated (now Analog Devices).

- Ethernet cameras – Ethernet cameras use the globally popular ethernet interface for transferring image data.

To learn more about USB, MIPI, and FPD-Link cameras, check out the below articles:

UVC USB Camera Modules – Why They are Preferred in Most Embedded Camera Systems

MIPI Cameras – Definition, Types and Applications

FPD-Link III Cameras – Working Principle and Applications in Embedded Vision

Advantages of compact camera modules

Owing to their small size, compact camera modules offer the following advantages:

- Since cameras take up less space in the vision device, more components (such as LiDAR for example) can be accommodated for additional functionalities.

- Compact camera modules make it possible to build low-weight and handheld vision-enabled devices such as industrial tablets.

- They make multi-camera integration easy by taking up minimal space in the overall system.

- Compact camera modules also come in different size variants (such as 30x30mm and 80x15mm) – making them perfectly suited for various architectural designs.

- Small form factor cameras enhance the aesthetic appearance of a vision system since they can be easily ‘hidden’ from outside view.

Applications of compact camera modules

In general, the compact design of camera modules has made product design convenient in almost any type of vision system. For example, consider a delivery robot. Though relatively large in size, a compact camera is always advantageous since the robot has to use multiple cameras. The same is the case with an autonomous tractor. However, small form factor cameras are not a must in these cases, especially if other feature sets take priority over size.

Here, let us look at some of the most compact embedded vision systems where a small form factor camera is a necessity.

Industrial handhelds

Industrial handheld tablets are used for the purposes of inspection, product logging, and inventory management. They are easy-to-handle portable devices that use small form factor cameras to capture images of objects on the go. Camera modules used in industrial tablets come with features such as auto focus, zoom, high resolution, and good color accuracy.

While some industrial handhelds use monochrome cameras, some others use color cameras. The choice of chromaticity is decided by the end application requirements.

Wound measurement devices

Wound measurement devices are portable devices used to measure the dimensions of a wound during the treatment process. The length, width, and depth of the wound are used to arrive at the right treatment methodology. This data is also used to assess the treatment and healing progress. Wound measurement devices use small form factor cameras to capture images.

While some industrial handhelds use monochrome cameras, some others use color cameras. The choice of chromaticity is decided by the end application requirements.

Intraoral cameras

Intraoral cameras are used by dentists to inspect gum and teeth. They allow dental care professionals to access and view areas that are otherwise difficult to see even with the aid of mirrors. Intraoral cameras are compact portable devices fitted with a high-resolution camera. Compact camera modules can be integrated smoothly into them due to their size and design advantages.

Handheld fundus and retinal cameras

Eye imaging is critical in ophthalmology. The accuracy of diagnosis depends heavily on the details of the images obtained. Fundus and retinal cameras – as the names suggest – are used to capture details of the retina and the fundus to treat and diagnose conditions like retinopathy, glaucoma, optic atrophy, etc. These cameras can be either desk-based or handheld. While the former can have slightly larger camera modules, the latter would find a better fit in compact camera modules.

Document scanners

Document cameras are used for scanning documents like passports, identity cards, contract agreements, etc. They are also used as a learning aid by students with low vision. Some of the modern document cameras also come with the OCR (Optical Character Recognition) capability where they can not only scan but read the text in a document or book. This is extremely useful for blind or low-vision students.

In all these use cases, a high-quality camera is essential. Since document cameras are small, a compact camera module is a must. The camera also has to come with high resolution and small pixel size to ensure it can comfortably capture tiny letters and graphs in books and documents.

Digital microscopes

Modern microscopes used for medical and life science applications leverage cameras to view and analyze the specimen. Cameras give researchers and lab personnel an enhanced view of the sample. In addition, using camera modules also enables AI/ML-based analyses using computer vision software. Small form factor cameras are best suited for all these purposes.

With advancements in sensor technology, camera modules today offer high resolution and a small pixel size with small form factor (A small pixel size in cameras helps to capture more minute objects and details).

Blood count analyzers

Blood count analyzers are used to count various kinds of blood cells. While early cell counters used to be bulky, next-gen blood diagnostic devices are compact and portable. The availability and high performance of compact camera modules is one of the reasons that accelerated the development of smaller blood cell counters.

TechNexion – compact camera modules for the smart world

As they say, small is the new big. Embedded vision is expanding imaging capabilities of smart devices by enabling a sleeker design. TechNexion is one of the few players to embark on the journey of building compact embedded cameras that power some of the new-age vision systems like medical devices, robots, and smart traffic devices. We also bring to the table unmatched engineering expertise and a state-of-the-art manufacturing facility to ensure we stick to the highest quality standards. Learn more about our embedded vision solutions.