Automation has and is continuing to significantly impact the industrial sector, integrating technologies such as robots, inspection cameras, and drones into operational workflows. One of the key requirements of these systems and the components used in them is the ability to withstand harsh industrial conditions. Challenges such as high temperature, high pressure, frequent shocks & vibrations, exposure to harmful materials are some of the adverse conditions they must face on a day-to-day basis.

When it comes to cameras, they must be resilient and capable of withstanding challenging conditions such as fluctuating temperatures, exposure to dust, and mechanical vibrations while still maintaining reliable performance. They must have industrial-grade protection to operate effectively and consistently produce high-quality images. This durability is important for reducing interruptions and enhancing efficiency in industrial settings.

Waterproof Camera

In this blog post, we explore the steps taken by camera manufacturers like TechNexion to ensure embedded cameras are durable and have an extended MTBF (Mean Time Between Failure) in harsh industrial and outdoor environments.

Steps taken to protect embedded cameras in industrial settings

Several measures are taken to ensure the durability of cameras under adverse industrial conditions. However, it is to be understood that not every camera used in an industrial application requires all the protections we will be presenting. The types of protection needed will depend entirely on the end application. Here, we will comprehensively create a complete understanding of the topic.

High-temperature resistance

Industrial cameras must be able to withstand and function reliably under extreme temperatures, from freezing cold to scorching heat. Take TechNexion’s VLS-FPD3-AR0234 (an AR0234 global shutter camera) for instance, it is engineered to be able to endure high temperatures and is perfect for harsh environments such as metal foundries or chemical plants. It comes with an operating temperature range of -30°C to +70℃. This resilience is the byproduct of using robust materials and components that can handle thermal stress, guaranteeing the camera’s durability and dependability. This feature also ensures that the camera can be used in any part of the world throughout the year in diverse weather conditions.

IP68 enclosure

To safeguard cameras against dust, rain, and snow in outdoor or industrial settings, TechNexion uses an IP68 enclosure for our FPD-LINK III and GMSL2 cameras. This rating guarantees top-notch protection from dust intrusion and prolonged water immersion in certain conditions. By placing the camera within an IP68-rated enclosure, TechNexion guarantees reliable operation even in challenging environments, ensuring it remains unharmed by water or particulate threats.

For example, VLS-FPD3-AR1335-C-S85-IR from TechNexion comes with an IP68 enclosure, ensuring superior protection from adverse weather. This helps extend the camera’s life and makes it suitable for use in any region.

FPD-Link III Aluminium Enclosed Camera with onsemi AR1335 13MP Rolling Shutter with Onboard ISP + S-mount Lens with IR-Cut Filter

VLS-FPD3-AR1335-SL

- onsemi AR1335 13MP Rolling Shutter Sensor

- 4K HDR Imaging for Low-Cost Applications

- S-Mount for Interchangeable Lenses

- FAKRA Z-Code Automotive Connector

- Plug & Play with Linux OS & Yocto

- VizionViewer™ configuration utility

- VizionSDK for custom development

Sturdy connectors and cables

The durability of a camera system is greatly influenced by the strength and reliability of its connectors and cables. For instance, TechNexion cameras are equipped with FAKRA connectors, renowned for their ability to endure extreme conditions such as shocks and vibrations. These connectors are crucial in establishing a stable connection between the camera and its processing system, ensuring consistent performance and data integrity even in demanding industrial environments.

This makes our cameras suitable for use in applications such as:

- ADAS (Advanced Driver Assistance System)

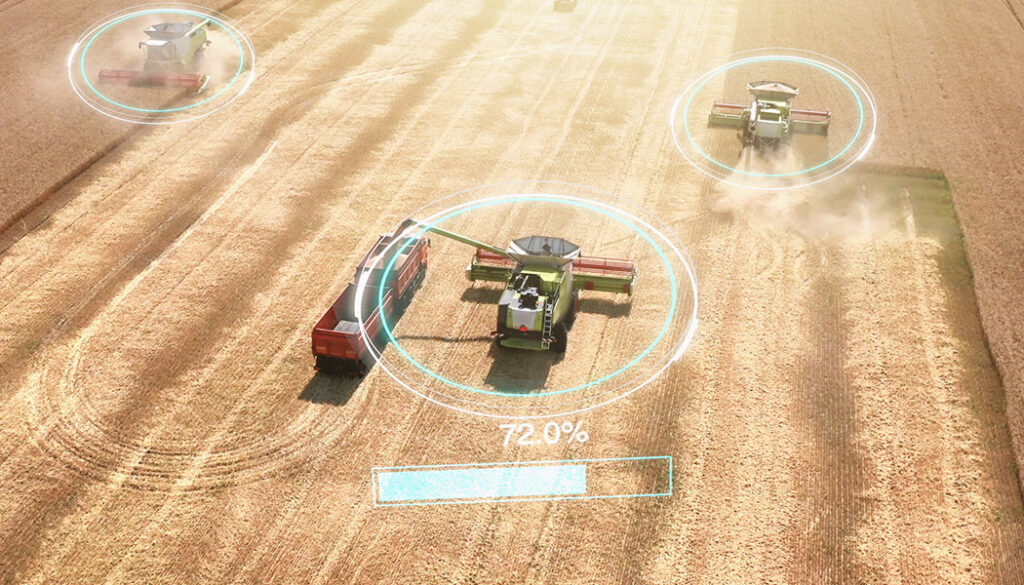

- Industrial and outdoor robots such as goods-to-person robots, pick-and-place robots, agricultural robots, etc.

- Autonomous tractors and automated forklifts.

Autonomous tractors

High EMI and EMC tolerance

In cameras and embedded vision systems, electromagnetic interference (EMI) and electromagnetic compatibility (EMC) are essential for optimal performance. A high tolerance for EMI and EMC means that the device can function effectively without being affected by or affecting electromagnetic disturbances. This is especially important in industrial settings, where powerful machinery and electronic systems can produce strong electromagnetic fields. High EMI and EMC tolerance ensures accurate and reliable operation, protecting against potential data corruption or failures caused by interference.

Benefits of industrial-grade cameras

Industrial-grade cameras offer a variety of advantages specifically designed to meet the rigorous standards of harsh industrial settings.

Let us take a closer look at what sets these specialized cameras apart.

High-temperature and high-pressure tolerance

Durable cameras are crucial in harsh industrial environments where extreme temperatures and pressures are common such as mines, factories, and oil rigs. Industrial-grade cameras are designed to operate continuously without being affected by heat or pressure issues. This reliability enables consistent monitoring and inspection tasks to be carried out effectively, even in the most difficult circumstances.

Shock and vibration resistance

Mobile robots and automotive systems are always on the go, navigating rough terrains and unpredictable surroundings. To withstand this demanding environment, industrial-grade cameras come equipped with robust connectors like the FAKRA connector, renowned for its ability to resist shocks and vibrations. This resilience ensures uninterrupted data transmission and reliable camera performance in mobile applications where disruptions are not an option.

Some of the other embedded vision applications where shock and vibration resistance are necessary include:

- Surround-view systems are used in large trucks and mining vehicles.

- Industrial inspection cameras

- Smart buses

- Autonomous tractors

- Automated forklifts

Automated Forklift

Extended Mean Time Between Failure (MTBF)

Specialized industrial cameras offer a boosted MTBF, signaling a longer lifespan than standard cameras, the extended durability is a crucial benefit, slashing the need for frequent replacements and upkeep, ultimately cutting costs and minimizing operational downtime in industrial settings.

With the ability to resist high temperature, high pressure, shocks, vibrations, and other adverse weather conditions, the MTBF can be extended by up to 50 to 60%. For example, some TechNexion cameras have an average MTBF of over 7 years.

Compliance with industry standards

Numerous industries enforce strict safety and operational regulations to safeguard workers and maintain process reliability. Industrial cameras are specifically crafted to comply with these standards, boasting features such as IP68 enclosures that shield against dust, rain, and snow. Using high-quality cables with strong coatings also enhances safety by protecting workers from electric shocks and burns.

Why TechNexion cameras are industrial-ready?

TechNexion cameras are well-suited for industrial environments, thanks to their design and features tailored to meet rigorous demands. The VLS-FPD3-AR0234 model is a prime example, showcasing the qualities that make these cameras ideal for industrial use. One key feature of the VLS3-AR0234 camera is its utilization of the FPD-Link III interface, renowned for its reliability in transmitting high-definition video and data across long distances. This interface is complemented by industrial-grade cables, ensuring stable connections even in challenging industrial conditions with high electromagnetic interference or physical stresses.

The camera’s FAKRA connector is well-known for its durability against shocks and vibrations. This feature is essential in industrial settings where machinery and operations can cause strong mechanical disturbances. The reliable FAKRA connector ensures a secure connection for the camera, allowing it to deliver consistent performance without disruptions.

The VLS3-AR0234 handles high operating temperatures, a critical feature for various industrial settings like factories, mines, and oil rigs. Its ability to perform consistently across a wide temperature range ensures reliable operation even in extreme conditions, preventing any heat-related malfunctions. The camera is securely housed in an IP68 enclosure, providing top-notch protection against dust and water ingress. This rugged design makes it perfect for outdoor environments and manufacturing processes involving liquids or particulates.

Like the VLS3-AR0234, TechNexion offers more top-of-the-line cameras designed to cater to the diverse requirements of vision systems such as robots, drones, smart traffic devices, sports broadcasting and analytics devices, and more. Talk to us today to elevate the performance of your vision system by using world-class cameras.

Related Products

Get a Quote

Fill out the details below and one of our representatives will contact you shortly.