Pixel binning is an imaging technique used in cameras to improve the quality of the output image by enhancing sensitivity. Whether in mobile phone cameras or embedded camera modules, the principle is the same for pixel binning. It is also called image binning or camera binning.

Enhancing sensitivity ensures that many high-resolution cameras can deliver clear images despite their small pixel size.

Sounds too complicated? Let’s decode pixel binning and all its related concepts in this article.

A Few Basic Concepts of Camera Technology

Pixel binning might be a complex topic if you are completely new to camera and sensor technology. Learning a few camera concepts first will help you develop a foundational understanding before we get into the details of how pixel binning or image binning works.

Following are the basic terminologies you need to understand:

- Pixels

- Pixel size

- Resolution

What is a Pixel?

The Architecture of An Image Sensor

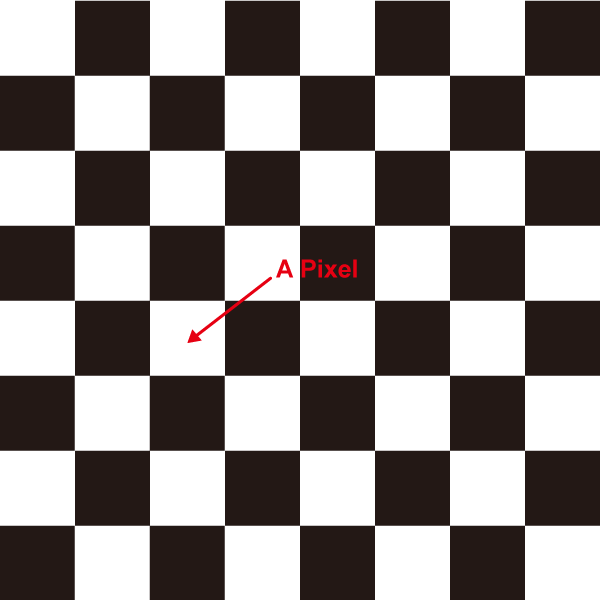

A pixel is the most basic unit of a sensor that collects the light falling on it. It is also called a photosite.

Sensors are constituted of thousands or millions of pixels (depending on what the resolution is) that stack together like a matrix as shown in the image.

Pixels are not flat two-dimensional structures.

Rather they have a well-like structure that is designed for them to collect light that can be converted into electric signals.

Pixel Size

Pixel size is nothing but the size of an individual sensor pixel. The larger the pixel, the higher will be the amount of light it can collect. It is usually expressed in micrometers (or microns). 1 micron equals 1 millionth of a meter (10-6).

In the most commonly used embedded camera modules, pixel size can vary from 1 micron to more than 4 microns. A pixel size of more than 2 microns is typically considered large.

For example, VCI-AR0821-CB, an AR0821-based C-mount camera from TechNexion, comes with a pixel size of 2.1 microns. This would mean that each pixel would be a square-shaped well with a length of 2.1 microns. This can be considered a large-pixel camera.

Another example is VCI-AR0822-CB, an AR0822 camera that comes with a pixel size of 2.0 microns.

Resolution

Resolution is the total number of pixels in a sensor or a camera. As resolution increases, the number of pixels also increases. This leads to improved quality of images owing to less pixelation in a given area of the image or scene. However, many other parameters determine the quality of an output image (which is also one of the reasons why pixel binning is required in cameras).

The resolution of a camera is obtained by multiplying the number of vertical columns and horizontal rows. For instance, a Full HD sensor comes with 1920 columns and 1080 rows. When the two are multiplied, the value obtained rounded off to the closest million would be 2 million pixels. This is what is more commonly expressed as 2 megapixels (MP). This means that a camera with a resolution of 13MP(like TechNexion’s VCI-AR1335-CB, a 13MP AR1335 camera) would have approximately 13 million pixels.

USB3 Type-C Aluminium Enclosed Camera with onsemi AR0822 8MP 4K Rolling Shutter with Onboard ISP + IR-Cut Filter + Incl. 1 Meter USB C Cable with C Mount Body

VCI-AR0822-CB

- onsemi AR0822 8MP Rolling Shutter Sensor

- 4K HDR Imaging Capabilities

- Near Infra-Red Enhancement for Outdoor Applications

- Designed for Low Light Applications

- C-Mount for Interchangeable Lenses

- UVC USB Type-C 5 Gbps Connector

- Plug & Play with Windows & Linux OS

- VizionViewer™ configuration utility

- VizionSDK for custom development

| Sensor | onsemi AR0822 |

| Shutter | Rolling |

| Megapixels | 8MP |

| Chromaticity | Color, Monochrome |

| Interface | USB3 |

What is Pixel Binning?

Now that you understand the associated camera concepts, let’s explore pixel binning.

Many modern embedded vision applications require cameras with very high resolution (often over 10MP). High resolution means a higher number of pixels, which in turn means that the sensor increases in size. However, owing to form factor constraints, sensors can’t go beyond a certain limit in terms of size. This has led to sensor manufacturers reducing pixel size (such as 1.1 microns in AR1335).

As pixel size reduces, the sensitivity of the sensor also goes down significantly as smaller pixels can only absorb less quantity of light. This could lead to poor image quality, especially in low-lighting conditions.

So how do you address this problem in high-resolution cameras?

This is where pixel binning comes in.

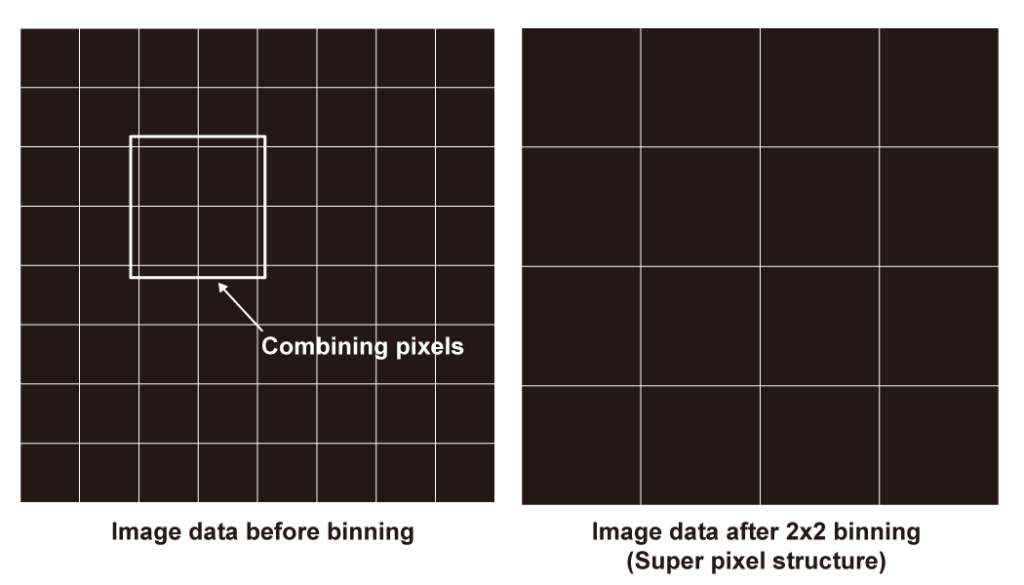

Pixel binning is the process of combining data from multiple pixels into one. This gives the new ‘super pixel’ access to more photons without having to play with the frame rate or exposure time.

The most popular form of binning is 2X2 binning where 4 adjacent pixels are combined to form the super pixel. This results in the reduction of resolution by a quarter. For instance, if you are applying 2×2 binning on a 12MP camera, your effective resolution after binning will be 3 MP.

Pixel binning offers the following advantages to embedded vision system manufacturers:

- One of the methods used to achieve the desired image quality in embedded cameras in low lighting conditions is increasing the exposure time. But this forces a compromise in the frame rate. Pixel binning, on the other hand, helps to achieve almost the same results without making any changes to the exposure time.

- Image outputs after binning tend to have less noise since there is less amount of image data/pixels to be handled.

- In situations where you don’t have the flexibility to go for a larger pixel camera, binning is a lifesaver.

- It gives you the option of switching between the high-resolution mode and the binning mode as required.

Pixel Binning in Monochrome and Color Cameras

In monochrome cameras, binning simply combines the data of the adjacent pixels as shown in the image:

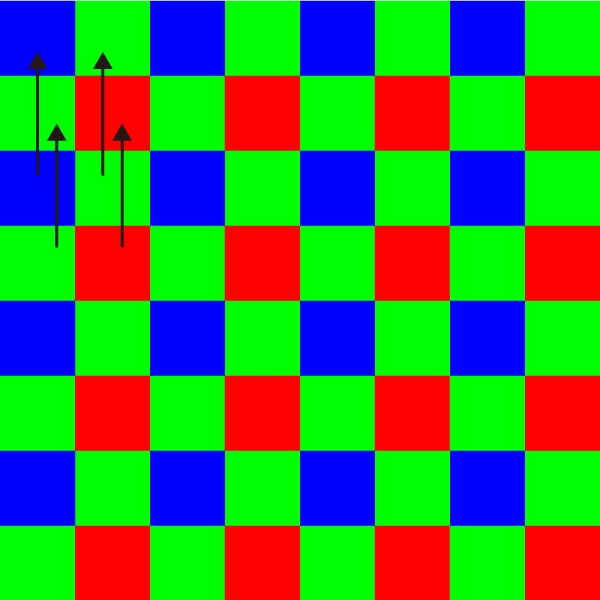

The difference when it comes to color cameras is that they use a CFA (Color Filter Array) leading to the formation of the Bayer patten on the sensor.

Here, pixel binning works differently by combining the pixel values of adjacent pixels of the same color as shown in the illustration:

As you can see in the image, the pixel values of similar pixels are combined or averaged to collect more photons.

Pixel Binning in Color Cameras

Working Principle of Pixel Binning

The data from multiple pixels is combined with the help of an ISP (Image Signal Processor) during the demosaicing process. Depending on the type of binning you use, the number of pixels to be combined might change. While 2×2 binning involves combining 4 pixels, a 3×3 binning process combines 9 pixels. Some latest smartphone cameras come with 16 to 1 or 4×4 binning. However, this is not much in use in the embedded camera world.

The practice of using a Quad Bayer is also in place. Unlike the normal Bayer filter where a packet of 4 pixels contains 2 green, 1 red, and 1 blue pixel, the Quad Bayer combines all four pixels in the pack to form a super pixel with 1 color. The Quad Bayer follows the same composition as that of the normal Bayer pattern (50% green, 25% red, and 25% blue).

Why is Pixel Binning Even Required?

One obvious question that comes to our mind is if pixel binning is done to increase the effective pixel size, why not use a camera with that pixel size in the first place?

It’s ideal if you do it that way if resolution is not a priority for you. A sensor that comes with a specific pixel size tends to give a better output than a sensor that achieves that pixel size using binning.

But there are a couple of practical reasons why embedded vision system designers like robotic engineers or smart traffic manufacturers don’t prefer to do so.

The first one is a practical reason where if the embedded vision device operates in locations with varying light supply, binning might have to be performed to enhance the sensitivity of the camera under certain lighting conditions.

The second is more of a business reason where manufacturers want to boast a high resolution for their camera-based products (say 4K) for marketing purposes. To achieve higher sensitivity in such scenarios, pixel binning is often used. We see this being applied a lot in the smartphone camera market where manufacturers use resolution as a marketing lever while all their cameras are using binning to enhance image quality.

TechNexion: Helping You with Everything Camera

TechNexion sees engineering at the core of everything it does. With an unmatched experience of 2 decades in the embedded space with a diverse set of products including embedded cameras, system on modules, panel computing solutions, etc., we know what it takes to build a great product.

Embedded vision has been one of the key areas of innovation for us where we combine our engineering expertise with active R&D (Research & Development) efforts to design cameras our customers want. As a part of this, we support our customers with all forms of integration and customization – whether it’s pixel binning, picking the right frame rate, or any other camera requirements of the application.

To learn more about our embedded vision products, please visit the embedded vision cameras page.

Related Products

Get a Quote

Fill out the details below and one of our representatives will contact you shortly.