The camera interface is the core of every embedded vision system, serving as more than just a data channel. It is essential for ensuring the system’s output quality, speed, and precision. One of the key challenges in attaining the desired quality in embedded vision systems in the early days was the lack of an interface that could transfer high-bandwidth data. However, a lot has changed in the last few years in camera interface technology.

This blog post will cover widely used interfaces such as USB, MIPI, and Ethernet, as well as SerDes technologies like FPD-Link and GMSL. We will analyze their strengths and weaknesses. Whether you decide on resolution, frame rate, transmission distance, host platform compatibility, latency, cost, or ease of integration, this guide offers clear insights into making informed choices.

What is embedded vision? How is it different from machine vision?

Embedded vision and machine vision are two distinct technologies that allow machines to perceive their surroundings visually, each with specific functions and applications.

Machine vision

- Definition and function: Machine vision allows computers or machines to understand and interpret visual data by utilizing cameras, image-processing software, and hardware components to capture, analyze, and make decisions based on visual information.

- System characteristics: These systems frequently rely on industrial or commercial PCs to manage the computational workload. They are equipped with specialized hardware and software for efficient image analysis and processing of visual data.

- Applications: Machine vision is commonly employed in environments requiring high levels of precision and computational capability, such as manufacturing quality control. In this context, it can detect defects, guide assembly robots, or track items as they move through a production line.

Embedded vision

- Definition and function: Embedded vision is the seamless integration of processing capabilities directly into the vision device. This enables real-time interpretation of visual data on-device and on-board, delivering valuable insights. This integration’s compactness, reduced operational costs, and immediate responsiveness make it highly advantageous.

- System characteristics: Embedded vision systems are characterized by compactness and ease of integration, processing data on-device or on-board. This makes them particularly suitable for applications where space and power efficiency are crucial.

- Applications: Common applications include drones, autonomous vehicles, smart traffic devices, and various Internet of Things (IoT) devices. These systems enable autonomous decision-making based on visual information by integrating embedded cameras with processors such as TI Jacinto TDA4VM, NVIDIA Jetson Orin, and NXP i.MX8, and others.

When it comes to interfaces, both embedded vision and machine vision systems use different types. This article focuses on camera interfaces used in embedded vision systems.

Read more about the similarities between embedded vision and machine vision here: Embedded Vision vs. Machine Vision – Everything You Need to Know.

The role of an interface in an embedded vision system

The interface plays a vital role in an embedded vision system by facilitating smooth and rapid data transfer from the camera to the processor while preserving intricate details. To ensure efficient operation, this requires a comprehensive understanding of camera interfaces, including their data transmission abilities, bandwidth, and technical specifications.

USB interfaces

The USB 2.0 and USB 3.0/3.1 standards serve different purposes in the realm of connectivity. USB 2.0, an earlier version, gained popularity due to its seamless plug-and-play functionality and affordability, making it suitable for applications with lower frame rates. On the other hand, the subsequent iteration, USB3.0/3.1, provides enhanced data transfer speeds while retaining plug-and-play capabilities and adhering to USB3 Vision standards. Despite offering improved bandwidth and efficiency, USB 3.0 is generally limited to cable lengths of 5 meters; however, this restriction can be overcome by utilizing active and optical cables for extension purposes. But again, this could affect parameters like bandwidth and latency.

GMSL

GMSL (Gigabit Multimedia Serial Links) is another popular SerDes interface. Maxim Integrated developed it with features similar to those of FPD-Link. They can transmit data up to a distance of 15 meters with a maximum bandwidth of 6 Gbps. Though the latest version of the interface is GMSL3, GMSL2 is more popular among product developers owing to its widespread adoption, particularly in the automotive sector.

VLS-GM2-AR0521-CB – AR0521 GMSL2 camera

FPD-Link III

FPD-Link III is a Serializer Deserializer (SerDes) interface commonly utilized in embedded vision and automotive systems. It facilitates the transmission of image and video data over twisted pairs or coaxial cables, along with bidirectional control data and power through Power Over Coax technology. Cameras equipped with FPD-Link III boast a maximum bandwidth of 4 Gbps, can transmit data up to 15 meters, and are resilient against shocks and vibrations. These cameras are well-suited for applications that demand high-quality, low-latency, long-distance data transmission, such as robotics, smart traffic devices, surround view systems, and drones.

The latest generation of SerDes from TI is FPD-Link IV, with a 2x increase in camera bandwidth (up to 8 Gbps) at the same distance of up to 15 meters.

MIPI interface

The MIPI interface is one of the most common interfaces in embedded vision today. It comes with a maximum bandwidth of 2.5 Gbps per lane and can reliably transmit data up to a distance of 25-30 cm.

Embedded vision often involves analyzing video streams from several cameras using a single processing system. This is common in applications such as surround view cameras and robotic navigation systems, which use MIPI Virtual Channels (VCs) to transmit multiple video streams over a single MIPI-CSI2 interface. However, this setup necessitates a specialized MIPI-CSI2 hub to combine and coordinate the independent camera streams.

Also read: Multi-Camera Systems in Embedded Vision: Features and Applications

Factors to consider while choosing the camera interface

When choosing a camera interface for embedded vision systems, consider the factors below to ensure optimal performance and integration.

Resolution and frame rate:

Most modern camera interfaces are ideal for achieving high resolution and frame rates. USB 3.0 can offer a maximum bandwidth of 480 MB per second or 3840 Gbps, while GigE offers a bandwidth of 120 MB per second. On the other hand, GMSL2 and FPD-Link III can offer bandwidths of about 6 Gbps and 4 Gbps, respectively. Regarding MIPI, the maximum bandwidth the MIPI interface can offer is 10 Gbps (with four lanes).

All the other interfaces mentioned above are suitable for ultra-high resolution cameras except for GigE.

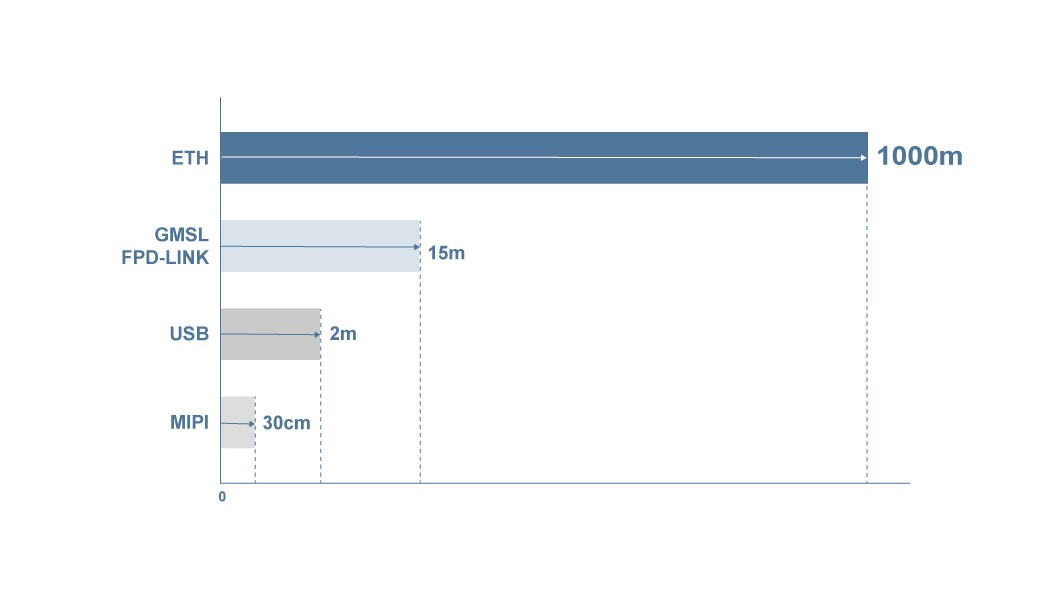

Distance of transmission:

MIPI and USB have different length limitations, with MIPI being limited to 30 cm and USB to 2 meters. However, certain USB variants can exceed the 5-meter limit, although this may come with compromises in quality or bandwidth. On the other hand, FPD-Link III is a SerDes interface that can transmit data up to 15 meters without sacrificing quality or latency. It is well-suited for applications that require long-distance data transmission. The same is the case with the GMSL interface.

The latest generation of SerDes from TI is FPD-Link IV, with a 2x increase in camera bandwidth (up to 8 Gbps) at the same distance of up to 15 meters.

Distance of transmission

Host platform compatibility:

USB is commonly utilized for x86-based hosts such as PCs, while MIPI is frequently employed with ARM processors, particularly in scenarios that involve multiple embedded cameras. MIPI Virtual Channels (VCs) can transport numerous video streams through a single interface, which necessitates a specialized MIPI-CSI2 hub for synchronization.

FPD-Link and GMSL, on the other hand, are SerDes interfaces that use a serializer on the transmitter end and a deserializer at the receiver end. They are commonly used with processors like TI Jacinto TDA4VM or NVIDIA Jetson,

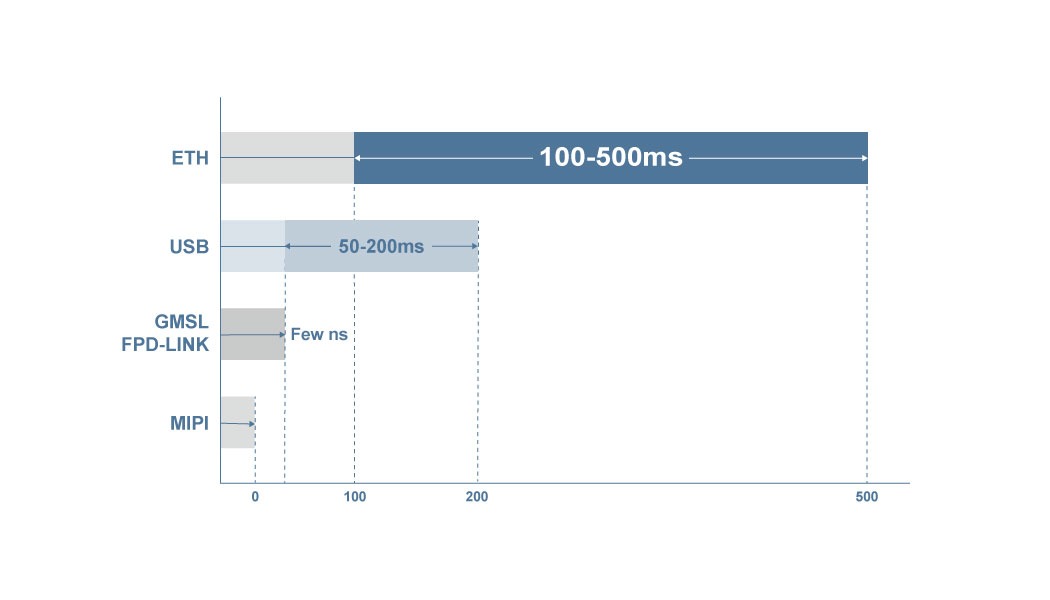

Latency

Latency is a critical factor in long-distance transmission, and interfaces such as FPD-Link and GMSL are known for their lower latency than Ethernet, which is particularly important in applications requiring quick decision-making and real-time data processing.

Difference in Latency between interfaces

Cost

The USB, Ethernet, and MIPI interfaces are usually more budget-friendly compared to the SerDes technologies such as FPD-Link and GMSL, which tend to be pricier due to their advanced features and additional components (like a serializer and a deserializer).

Ease of integration:

While USB and Ethernet interfaces provide easy plug-and-play functionality and are compatible with a wide range of devices, integrating MIPI interfaces may require extra setup or specific processors, potentially adding complexity to some systems.

TechNexion – cameras for a wide range of interfaces

TechNexion offers a diverse selection of embedded vision solutions that cater to the needs of embedded system developers seeking high-performance, industrial-grade camera options.

These cameras are specifically engineered to expedite the development process for embedded vision projects. TechNexion’s camera range encompasses a variety of interfaces tailored to different requirements. MIPI-CSI2, for instance, is widely utilized in embedded vision applications due to its rapid data transmission capabilities, making it well-suited for high-resolution and high-frame-rate applications (learn more about our MIPI cameras).

Meanwhile, USB3 Type C interfaces are renowned for their extensive bandwidth and adaptability, facilitating swift data transfer and efficient power delivery in numerous embedded vision systems (learn more about USB3 camera modules).

On the other hand, FPD-Link III stands out as an interface ideal for long-range data transmission while preserving superior quality and minimal latency. This makes it particularly suitable for industrial settings where resilience against mechanical shocks, water ingress, or high temperatures is essential (learn more about our FPD-Link III cameras).

For any help in integrating cameras into your embedded vision system, get in touch with us today.